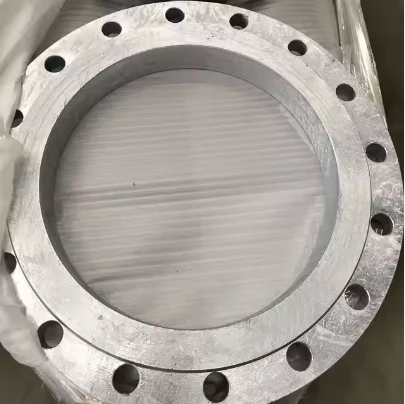

Laippa

Flanges are essential components in piping systems, connecting pipes, valves, pumps, and other equipment to form a secure and leak-proof assembly. When searching for a flange for sale, it's crucial to understand the various flange types and sizes available to ensure the right fit for your project. Flanges come in a wide range of designs, each suited for specific applications and requirements. We provide different flange types, including JIS b2220 flange, DIN-laippa, EN 1092 1 flange, and GOST-laippa, etc.

What Is a Flange Used For

There are multiple flange applications across a wide range of industries, including:

1. Pipeline Systems

In the oil and gas, water treatment, and chemical industries, flanges are crucial for connecting sections of piping. They allow for the easy assembly and disassembly of pipeline systems, facilitating maintenance and repairs. When joints need to be inspected or replaced, flanges provide a convenient solution.

2. Pressure Vessels

Flanges are often used in pressure vessels, where they must withstand high pressures and temperatures. They create a secure seal that is essential for maintaining safety and functionality, particularly in industries such as pharmaceuticals and food processing, where containment standards are critical.

3. Manufacturing Equipment

In manufacturing, flanges are commonly found in machinery and equipment. They join different components, enabling machinery to operate smoothly and effectively. Proper flange installation ensures that machines can perform at optimal levels without risk of failure.

4. Automotive Industry

Flanges also play a significant role in the automotive sector, where they connect various parts of a vehicle, including exhaust systems and transmission components. Ensuring that these flanges are correctly fitted is essential for vehicle performance and safety.

Flange Types and Sizes

Flanges are mechanical components that connect two systems or parts together, allowing for easy assembly and disassembly of piping systems. They are typically made from materials like steel, plastic, or other metals and are designed to create a strong, leak-proof seal when bolted together. Flanges come in various shapes and types, each suited for different applications and industries.

Types of Flanges

1. Weld Neck Flanges: These flanges have a long tapered neck that enables gradual transition from pipe to flange. This design minimizes stress concentration and is best suited for high-pressure applications.

5. Threaded Flanges: As the name implies, these flanges have internal threads that allow them to be screwed onto the piping system. They are ideal for applications where welding is impractical.

Understanding Flange Sizes

When selecting flanges, one of the most crucial factors to consider is the flange size. Flange sizes are designated based on the nominal pipe size (NPS) and pressure class. The right flange size ensures compatibility with your entire piping system and helps maintain system pressure.

Flange sizes are determined by:

- Nominal Pipe Size (NPS): This refers to the diameter of the pipe and is critical when selecting the appropriate flange. Flanges come in various NPS sizes ranging from ¼ inch to 36 inch flange, and sometimes even larger.

- Pressure Ratings: Flanges are categorized by pressure ratings, which indicate the maximum pressure they can withstand. Common pressure classes include 150, 300, 600, and higher.

- Dimensions: Flange dimensions, including the bolt circle diameter, bolt size, and thickness, vary depending on the type and standard (such as ANSI or ASME).

Importance of Choosing the Right Flange Size

Selecting the correct flange size is essential for several reasons:

- Prevention of Leaks: A mismatched flange size can lead to gaps, resulting in leaks and unsafe conditions.

- System Efficiency: Correctly sized flanges ensure smooth flow and reduce turbulence, which enhances system performance.

- Compliance: Adhering to industry standards and specifications is critical for regulatory compliance, ensuring the safety and efficiency of your systems.

Why Choose Flange Manufacturer in China

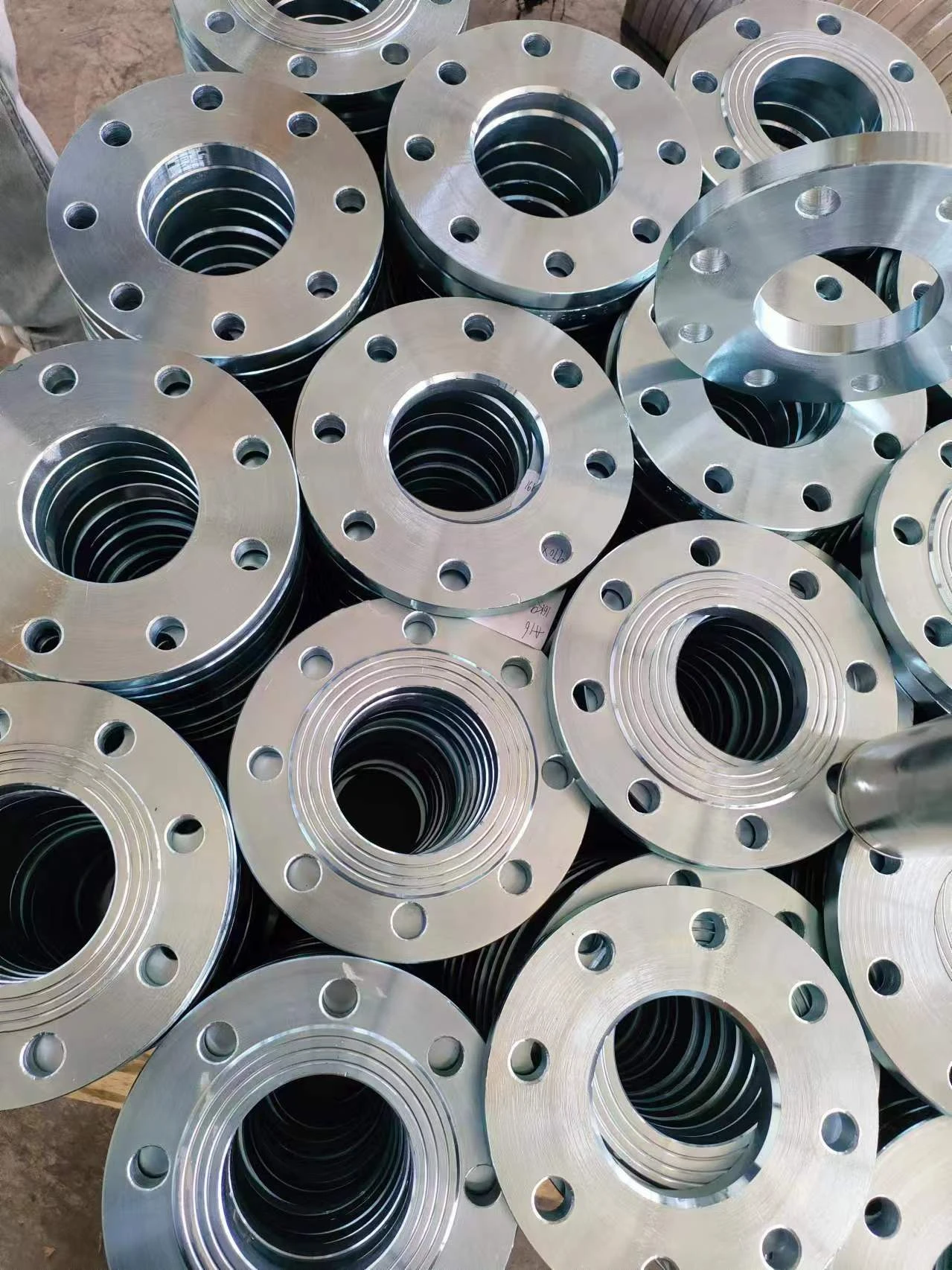

When it comes to sourcing flanges, it’s essential to partner with a reliable and reputable flange manufacturer in China. Among the myriad of options available, Yulong Flange Manufacturer stands out as a top choice.

Laatuvakuutus

One of the most significant factors to consider when choosing a flange manufacturer in China is the quality of the products. Yulong Flange Manufacturer is renowned for its unwavering commitment to quality. Their flanges undergo rigorous quality control processes to adhere to international standards. By opting for Yulong, you can rest assured that you are investing in durable and reliable products that meet your specific requirements.

Extensive Product Range

Yulong Flange Manufacturer offers an extensive range of flanges, catering to various industries and applications. Whether you require ANSI, DIN, or JIS standard flanges, Yulong has got you covered. Their diverse product line ensures that you can find the exact type of flange suited to your project needs. This wide selection makes Yulong a one-stop shop for all your flange requirements, saving you time and effort in sourcing multiple suppliers.

Competitive Pricing

In an increasingly competitive market, pricing is a critical factor. Yulong Flange Manufacturer in China provides excellent value for money without compromising on quality. Their efficient manufacturing processes and economies of scale enable them to offer competitive flange prices, making them an attractive option for bulk orders. Partnering with Yulong means you can maximize your budget while still obtaining top-notch products.

Advanced Manufacturing Techniques

Yulong is at the forefront of innovation in the flange manufacturing industry. Utilizing the latest technology and advanced manufacturing techniques, Yulong Flange Manufacturer ensures precision and consistency in every product they create. This commitment to technological advancement means you receive flanges that are not only of high quality but also manufactured to the exact specifications required for your applications.

Exceptional Customer Service

Choosing the right flange manufacturer in China is not just about the products; it's about the overall experience. Yulong Flange Manufacturer prides itself on its customer-centric approach. Their dedicated team is ready to assist you throughout the entire process, from initial inquiries to post-purchase support. Their responsiveness and willingness to go the extra mile set them apart from the competition, providing you with peace of mind as you complete your projects.

Proven Track Record

Yulong Flange Manufacturer has built a solid reputation over the years as a reliable supplier in the industry. With numerous successful projects and satisfied clients, they have established themselves as a trusted partner for companies worldwide. Their proven track record gives you the confidence that you are choosing a flange manufacturer in China with the experience and expertise to deliver on their promises.

In conclusion, if you are looking for a flange manufacturer in China, Yulong Flange Manufacturer is undoubtedly a wise choice. With their focus on quality, extensive product range, competitive pricing, advanced manufacturing techniques, exceptional customer service, and proven track record, Yulong is well-equipped to meet your flange needs. When you partner with Yulong, you are not just purchasing flanges; you are investing in a relationship with a manufacturer that values quality, innovation, and customer satisfaction. Make the right decision today and choose Yulong Flange Manufacturer for all your flange requirements!