JIS B2311 se yon estanda Endistriyèl Japonè ki kouvri ekipman tiyo soude, ki gen ladan bouchon yo itilize nan sistèm kanalizasyon. Bout-soude bouchon sèvi pou yo fèmen fen yon tiyo, bay yon sele pou anpeche flit oswa kontaminasyon. Isit la se yon entwodiksyon nan bouchon soude JIS B2311:

- 1. JIS B2311 Standard:

- - JIS B2311 estanda presize kondisyon yo pou konsepsyon, dimansyon, materyèl, fabrikasyon, ak tès ekipman pou soude bou, ki gen ladan bouchon, nan sistèm kanalizasyon.

- - Estanda a asire ke bouchon ki pwodui an konfòmite ak estanda JIS satisfè estanda kalite epi yo konpatib ak lòt konpozan kanalizasyon.

- 2. Bou-soude bouchon:

- - Yon bouchon soude, dapre JIS B2311, se yon ekipman ki fèt pou kouvri ak sele fen yon tiyo an sekirite, ofri pwoteksyon ak kenbe entegrite nan sistèm nan kanalizasyon.

- - Bouchon yo itilize nan sitiyasyon kote fen tiyo a mande pou fèmen, swa pou tout tan oswa tanporèman, pou anpeche flit, kontaminasyon, oswa bay yon fini nan sistèm nan.

- 3. Materyèl ak konstriksyon:

- - Bou-soude bouchon anba espesifikasyon JIS B2311 yo disponib nan divès kalite materyèl tankou asye kabòn, asye pur, ak asye alyaj pou satisfè kondisyon aplikasyon diferan.

- - Bouchon sa yo fabrike lè l sèvi avèk metòd konstriksyon estanda pou asire yon koneksyon solid ak san koule lè yo soude nan fen yon tiyo.

- 4. Aplikasyon ak Benefis:

- - Bouton-soude bouchon jwenn aplikasyon nan endistri divès kalite, ki gen ladan lwil oliv ak gaz, pwosesis chimik, plant tretman dlo, ak plis ankò kote fini tiyo bezwen yo dwe bouche byen.

- - Bouchon bay pwoteksyon nan pwent tiyo kont eleman anviwònman an, anpeche kontaminasyon, epi ede kenbe pwòpte ak entegrite sistèm kanalizasyon an.

- 5. Enstalasyon ak soude:

- - Pratik enstalasyon apwopriye, ki gen ladan aliyman kòrèk, preparasyon nan fen tiyo a, ak teknik soude, yo esansyèl lè enstale bouchon-soude pou asire yon sele ki sere ak koule-prèv.

- - Soude se yon metòd komen pou tache bouchon nan tiyo, bay yon fèmen sekirite ak pèmanan ki ka kenbe tèt ak presyon, varyasyon tanperati, ak koule likid nan sistèm nan.

- An rezime, bouchon soude JIS B2311 yo se eleman enpòtan yo itilize nan sistèm kanalizasyon pou sele ak pwoteje fen tiyo an sekirite. Bouchon sa yo konfòme yo ak kondisyon estanda pou asire bon jan kalite, fyab, ak konpatibilite nan aplikasyon endistriyèl kote fèmen tiyo ak pwoteksyon yo nesesè.

What Is a Butt Welding Cap and How Is It Used in Industrial Piping?

In industrial piping systems, end-of-line sealing and branch closures require robust solutions. A butt welding cap serves as a critical component for terminating pipes securely. By providing a seamless, welded closure, this fitting maintains system integrity, prevents leaks, and supports compliance with industry standards.

What Is a Butt Welding Cap?

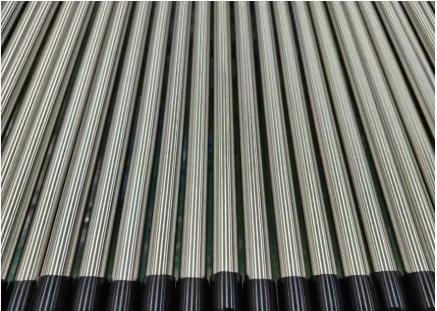

A butt welding cap—also called a pipe end cap or buttweld end cap—is a round fitting designed to close off the end of a pipe. It’s manufactured to match the pipe’s outer diameter and schedule, with either a hemispherical or flat face. To install, both the pipe end and cap are beveled to form a V‑groove, enabling full‑penetration, fusion welds. Common materials include carbon steel, stainless steel, nickel alloys, and other engineered grades, chosen to satisfy pressure, temperature, and corrosion‑resistance requirements.

How Is Butt Welding Cap Used in Industrial Piping?

Butt welding caps find application across oil & gas, petrochemical, power generation, water treatment, and general process industries for both permanent and temporary closures. During hydrostatic testing, technicians install caps to seal off sections of piping while monitoring for leaks. In new construction or retrofit projects, caps terminate branch lines, future tie‑in spools, or dead‑end mains until system expansion. Welders prepare each joint by cleaning and beveling surfaces, aligning the cap precisely, and executing a root pass followed by filler passes per the qualified Welding Procedure Specification (WPS). Post‑weld heat treatment and non‑destructive examination (NDE)—such as radiography or ultrasonic testing—verify weld integrity and compliance with ASME B16.9 and related standards. Additionally, temporary caps enable safe isolation during maintenance, allowing for segment testing and dewatering under regulatory protocols.

Benefits and Best Practices

Butt welding caps offer a smooth‑bore transition that minimizes flow disruption and stress concentration. Their full‑penetration welds deliver exceptional structural strength and leak resistance. To optimize performance, engineers should:

Select caps with matching material grades and wall thicknesses

Adhere to proper bevel angles and joint fit‑up tolerances

Follow qualified WPS protocols rigorously

Consider cladding or protective coatings in corrosive environments to extend service life

Regular inspection and thorough documentation ensure long‑term reliability and safe operation under demanding conditions.

Butt welding caps are indispensable components for achieving durable, leak‑proof pipe terminations in a wide range of industrial applications.

Butt Welding Cap FAQs

What is a butt welding cap?

|

What materials are commonly used?

|

What standards govern butt welding caps?

|

How are butt welding caps installed?

|

Where are butt welding caps typically used?

|

What are the advantages of threaded caps?

|