JIS B2311 dia fenitra ara-indostrialy japoney izay mandrakotra ny fametahana sodina sodina, ao anatin'izany ny satroka ampiasaina amin'ny rafitra fantsona. Ny satroka lasantsy dia mikendry ny hanidy ny faran'ny fantsona iray, manome tombo-kase mba hisorohana ny fivoahana na ny loto. Ity misy fampidirana ny JIS B2311 satroka lasantsy:

- 1. JIS B2311 Standard:

- - Ny fenitra JIS B2311 dia mamaritra ny fepetra takiana amin'ny famolavolana, ny refy, ny fitaovana, ny famokarana ary ny fitsapana ny fitaovana fanamafisam-peo, anisan'izany ny satroka, amin'ny rafitra fantsona.

- - Ny fenitra dia miantoka fa ny satroka vokarina mifanaraka amin'ny fenitra JIS dia mahafeno ny fenitra kalitao ary mifanaraka amin'ny singa fantsona hafa.

- 2. Cap-Welding Cap:

- - Ny satroka fandrefesana vody, araka ny JIS B2311, dia fitaovana natao handrakofana sy hamehezana tsara ny faran'ny fantsona iray, manome fiarovana sy mitazona ny fahamendrehan'ny rafitra fantsona.

- - Ny satroka dia ampiasaina amin'ny toe-javatra izay mitaky fanakatonana ny faran'ny fantsona, na maharitra na vonjimaika, mba hisorohana ny fivoahana, ny fandotoana, na ny famitana ny rafitra.

- 3. Fitaovana sy fanorenana:

- - Ny satroka lasantsy eo ambanin'ny fepetra JIS B2311 dia misy amin'ny fitaovana isan-karazany toy ny vy karbônina, vy tsy misy vy ary vy firaka mba hamenoana ny fepetra fampiharana samihafa.

- - Ireo satroka ireo dia amboarina amin'ny fomba fananganana manara-penitra mba hiantohana ny fifandraisana matanjaka sy tsy misy leaka rehefa atambatra amin'ny faran'ny fantsona.

- 4. Fampiharana sy tombony:

- - Mahita fampiharana amin'ny indostria isan-karazany ny satroka fandrefesana bozaka, ao anatin'izany ny solika sy ny entona, ny fizotran'ny simika, ny toeram-pamokarana rano, ary ny maro hafa izay tsy maintsy fehezina tsara ny fiafaran'ny fantsona.

- - Ny satroka dia miaro ny tendron'ny fantsona amin'ny singa ara-tontolo iainana, misoroka ny fandotoana, ary manampy amin'ny fitazonana ny fahadiovana sy ny fahamarinan'ny rafitra fantsona.

- 5. Fametrahana sy welding:

- - Ny fomba fametrahana araka ny tokony ho izy, anisan'izany ny fampifanarahana marina, ny fanomanana ny faran'ny sodina ary ny teknikan'ny lasantsy, dia tena ilaina amin'ny fametrahana satroka lasantsy mba hiantohana ny tombo-kase mafy sy tsy misy leak.

- - Ny welding dia fomba fanao mahazatra amin'ny fametahana satroka amin'ny fantsona, manome fanakatonana azo antoka sy maharitra izay mahatohitra ny tsindry, ny fiovan'ny mari-pana ary ny fikorianan'ny fluid ao anaty rafitra.

- Raha fintinina, JIS B2311 satroka sodina dia singa manan-danja ampiasaina amin'ny rafitra fantsona mba hamehezana sy hiarovana ny faran'ny fantsona. Ireo satroka ireo dia mifanaraka amin'ny fepetra manara-penitra mba hiantohana ny kalitao, ny fahamendrehana ary ny fifanarahana amin'ny fampiharana indostrialy izay ilaina ny fanakatonana sy ny fiarovana ny fantsona.

What Is a Butt Welding Cap and How Is It Used in Industrial Piping?

In industrial piping systems, end-of-line sealing and branch closures require robust solutions. A butt welding cap serves as a critical component for terminating pipes securely. By providing a seamless, welded closure, this fitting maintains system integrity, prevents leaks, and supports compliance with industry standards.

What Is a Butt Welding Cap?

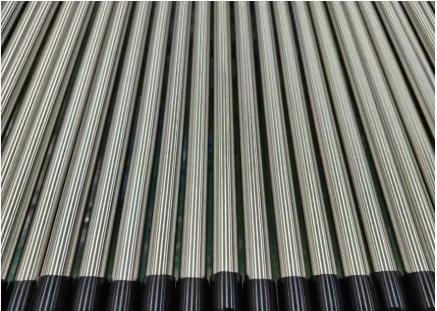

A butt welding cap—also called a pipe end cap or buttweld end cap—is a round fitting designed to close off the end of a pipe. It’s manufactured to match the pipe’s outer diameter and schedule, with either a hemispherical or flat face. To install, both the pipe end and cap are beveled to form a V‑groove, enabling full‑penetration, fusion welds. Common materials include carbon steel, stainless steel, nickel alloys, and other engineered grades, chosen to satisfy pressure, temperature, and corrosion‑resistance requirements.

How Is Butt Welding Cap Used in Industrial Piping?

Butt welding caps find application across oil & gas, petrochemical, power generation, water treatment, and general process industries for both permanent and temporary closures. During hydrostatic testing, technicians install caps to seal off sections of piping while monitoring for leaks. In new construction or retrofit projects, caps terminate branch lines, future tie‑in spools, or dead‑end mains until system expansion. Welders prepare each joint by cleaning and beveling surfaces, aligning the cap precisely, and executing a root pass followed by filler passes per the qualified Welding Procedure Specification (WPS). Post‑weld heat treatment and non‑destructive examination (NDE)—such as radiography or ultrasonic testing—verify weld integrity and compliance with ASME B16.9 and related standards. Additionally, temporary caps enable safe isolation during maintenance, allowing for segment testing and dewatering under regulatory protocols.

Benefits and Best Practices

Butt welding caps offer a smooth‑bore transition that minimizes flow disruption and stress concentration. Their full‑penetration welds deliver exceptional structural strength and leak resistance. To optimize performance, engineers should:

Select caps with matching material grades and wall thicknesses

Adhere to proper bevel angles and joint fit‑up tolerances

Follow qualified WPS protocols rigorously

Consider cladding or protective coatings in corrosive environments to extend service life

Regular inspection and thorough documentation ensure long‑term reliability and safe operation under demanding conditions.

Butt welding caps are indispensable components for achieving durable, leak‑proof pipe terminations in a wide range of industrial applications.

Butt Welding Cap FAQs

What is a butt welding cap?

|

What materials are commonly used?

|

What standards govern butt welding caps?

|

How are butt welding caps installed?

|

Where are butt welding caps typically used?

|

What are the advantages of threaded caps?

|