-

DIN2527 Standaard Voldoening:

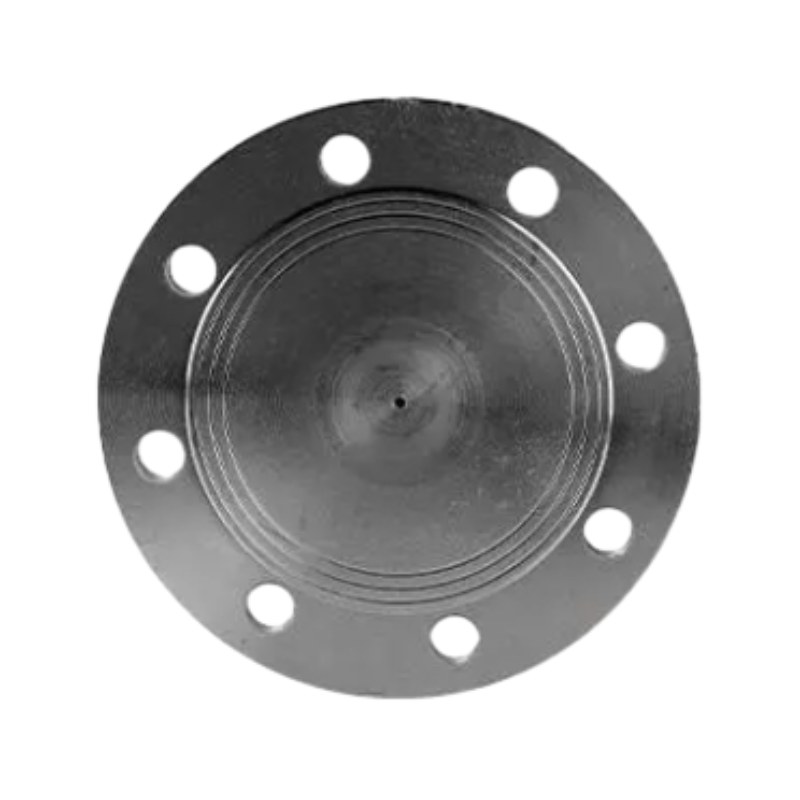

DIN2527 blinde flense voldoen aan die spesifikasies soos uiteengesit deur die Deutsches Institut für Normung (DIN), wat eenvormigheid en verenigbaarheid met ander DIN-voldoenende komponente verseker. Hierdie standaardisering vergemaklik die integrasie van blinde flense in pypstelsels, wat naatlose werking en instandhouding bevorder. - Verseëlde sluiting:

Blinde flense dien die noodsaaklike funksie om pyppunte of openinge in 'n pypstelsel te seël. DIN2527 blinde flense het 'n soliede, plat skyf met boutgate om die omtrek, wat dit moontlik maak om hulle stewig aan die bypassende flens of pypkant vasgebout te word. Hierdie verseëlde sluiting voorkom die lekkasie van vloeistowwe of gasse, wat die integriteit en veiligheid van die pypstelsel handhaaf. -

Veelsydige toepassings:

DIN2527 blinde flense vind toepassing in verskeie industrieë, insluitend olie en gas, chemiese verwerking, waterbehandeling, kragopwekking en skeepsbou. Hulle word in pypleidings, drukvate en opgaartenks gebruik om ongebruikte of tydelike openinge af te sluit, gedeeltes van pype te isoleer vir instandhouding of herstel, of as 'n manier van inspeksie en toetsing. -

Materiaalkeuse:

Blinde flense is beskikbaar in verskillende materiale om by verskillende bedryfstoestande en media te pas. Algemene materiale sluit in koolstofstaal, vlekvrye staal, legeringstaal en nie-ysterhoudende legerings soos koper of brons. Die keuse van materiaal hang af van faktore soos temperatuur, druk, weerstand teen korrosie en verenigbaarheid met die vloeistof of gas wat hanteer word. -

Drukgraderings:

DIN2527 blinde flense is ontwerp om spesifieke drukgraderings te weerstaan, wat wissel van PN6 tot PN100, volgens DIN-standaarde. Die drukgradering bepaal die maksimum toelaatbare druk wat die flens veilig kan weerstaan sonder om sy strukturele integriteit of seëlwerkverrigting in te boet. Dit is noodsaaklik om blinde flense met die toepaslike drukgradering vir die beoogde toepassing te kies om veilige en betroubare werking te verseker. -

Pasmaakopsies:

While DIN2527 blind flanges conform to standard dimensions and specifications, customization options are available to accommodate unique project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized blind flanges are often tailored to fit specific piping configurations and operating conditions.

What Is a Blind Flange?

A blind flange is a solid, circular plate used to seal off the ends of piping systems, valves, or pressure vessels. Unlike other different flange types, blind flanges lack a central bore, making them ideal for completely closing off a pipeline or opening. They are commonly utilized in various industrial applications, including oil and gas, chemical processing, water treatment, and power generation, where secure and leak-proof pipe closures are essential.

Blind flanges are available in a wide range of sizes and pressure ratings, conforming to industry standards such as ANSI, ASME, and DIN. Sizes range from small diameters, like a 2-inch blind flange, to larger options, such as 36 blind flanges, catering to diverse operational requirements. The design typically features bolt holes around the perimeter, allowing the flange to be securely fastened to a mating component, like a pipe flange or valve.

The primary purpose of a blind flange is to isolate sections of a pipeline for maintenance, testing, or system modifications without disrupting the entire operation. They also play a critical role in pressure testing, allowing operators to evaluate the system's capacity under specific conditions.

Materials for blind flanges include stainless steel, carbon steel, alloy steel, and other metals, ensuring compatibility with various operating environments, including high-temperature, high-pressure, or corrosive conditions. Some blind flanges also feature coatings or linings for additional durability.

Blind flanges are essential for ensuring safety, system integrity, and operational flexibility. Their robust design and adaptability make them indispensable in industrial piping systems, providing reliable sealing solutions and enhancing overall efficiency.

What Is a Blind Flange Used For

Pipeline Isolation

Blind flanges are commonly used to isolate sections of a pipeline for maintenance, repairs, or system upgrades. By sealing off the pipeline, operators can work on specific sections without interrupting the entire operation.

System Testing

In pressure testing scenarios, blind flanges enable operators to assess the strength and performance of the pipeline or vessel under controlled conditions. The flange helps maintain pressure within the system during testing, ensuring accurate results.

Future Expansion

Blind flanges can be installed at pipeline terminations where future expansions are anticipated. They temporarily seal the system, allowing additional components to be integrated later without significant modifications.

Safety in Shutdowns

During system shutdowns, blind flanges ensure that no residual fluids or gases escape, enhancing safety for maintenance crews and protecting the environment.

Preventing Contamination

In industries like food processing or pharmaceuticals, blind flanges are used to prevent contamination by securely sealing unused pipeline sections.

Blind Flange Types

Standard Blind Flanges

Standard blind flanges are flat, solid discs with no central bore. They are designed to fit a variety of piping systems and are often categorized by standards such as ANSI, ASME, and DIN. These flanges are versatile and used in applications with moderate pressure and temperature conditions.

Raised Face (RF) Blind Flanges

Raised face blind flanges feature a slightly elevated sealing surface. The raised face provides a better seal when paired with gaskets, making them suitable for higher-pressure applications in industries like oil and gas.

Flat Face (FF) Blind Flanges

Flat-face blind flanges have a uniform sealing surface that lies flush with the pipe flange. They are ideal for systems where flange surfaces must be evenly distributed to prevent damage, such as in low-pressure environments.

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges feature a grooved surface to accommodate metal gaskets. This design provides superior sealing, making them ideal for high-pressure and high-temperature systems, such as petrochemical plants.

Threaded Blind Flanges

Threaded blind flanges have threads on their inner surface, allowing them to be screwed directly onto a threaded pipe. They are commonly used in low-pressure systems and applications requiring quick assembly and disassembly.

DIN 2527 Blind Flange Advantages

The DIN 2527 blind flange is an essential component in piping systems, particularly in industrial applications where robust sealing is required. This type of flange offers several advantages, making it a preferred choice for many engineers and designers.

Firstly, one of the main benefits of the DIN 2527 blind flange is its ability to provide a secure and leak-proof seal. By covering the ends of pipes, it effectively blocks the flow, preventing any unwanted leaks or exposures. This is particularly critical in systems that transport hazardous materials, where safety and environmental protection are of utmost importance.

Secondly, the DIN 2527 blind flange is designed to withstand high pressure and temperature conditions, which ensures durability and long service life. Constructed from various materials, including stainless steel, carbon steel, and alloys, these flanges can be tailored to meet specific operational requirements, enhancing their reliability under extreme conditions.

Another advantage is the easy installation process. The blind flange can be easily bolted to the end of a pipe without requiring any special tools or complex techniques. This simplifies the assembly process and allows for quicker maintenance or modifications in the future.

Additionally, blind flanges are highly versatile and can be used in a range of applications, from oil and gas to water treatment and chemical processing. This versatility makes the DIN 2527 blind flange an excellent solution for diverse industries.

Moreover, using blind flanges can enhance the system's overall design by facilitating future expansions or modifications. Since they can be removed and replaced without extensive alterations to the piping layout, they provide flexibility in system management.

In summary, the DIN 2527 blind flange offers secure sealing, durability, ease of installation, versatility, and design flexibility, making it a vital component in many industrial piping systems. Its advantages contribute significantly to operational efficiency and safety, solidifying its status as a preferred choice in various applications.

DIN2527 blinde flense is onontbeerlike komponente in pypstelsels, wat 'n betroubare en lekvrye sluiting vir pyppunte of openinge bied. Hul nakoming van DIN-standaarde, veelsydigheid en aanpasbare opsies maak hulle geskik vir 'n wye reeks industriële toepassings waar digte verseëling en drukbeheer van kritieke belang is. Met DIN2527 blinde flense kan ingenieurs en operateurs die integriteit, veiligheid en doeltreffendheid van hul pypstelsels verseker, wat bydra tot gladde en probleemvrye bedrywighede oor nywerhede heen.