-

DIN2527 الامتثال القياسي:

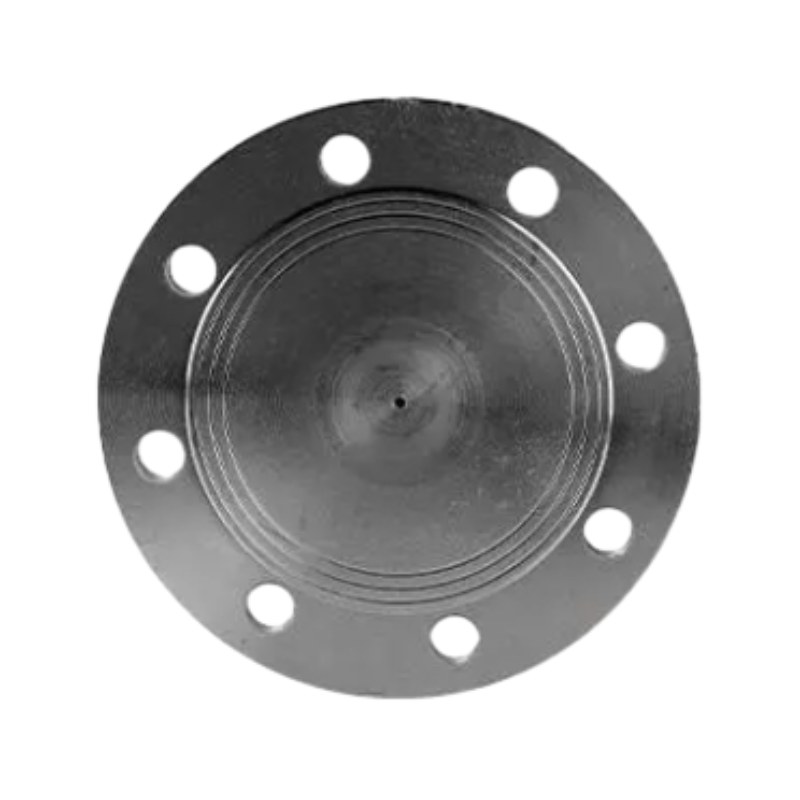

تلتزم الحواف العمياء DIN2527 بالمواصفات التي حددها Deutsches Institut für Normung (DIN)، مما يضمن الاتساق والتوافق مع المكونات الأخرى المتوافقة مع DIN. يعمل هذا التقييس على تبسيط عملية دمج الفلنجات المسدودة في أنظمة الأنابيب، مما يعزز التشغيل والصيانة السلسة. - إغلاق مختوم:

تخدم الشفاه العمياء الوظيفة الأساسية لإغلاق نهايات الأنابيب أو الفتحات في نظام الأنابيب. تتميز الفلنجات العمياء DIN2527 بقرص صلب ومسطح مع فتحات مسامير حول المحيط، مما يسمح بتثبيتها بشكل آمن على شفة التزاوج أو نهاية الأنبوب. ويمنع هذا الإغلاق المحكم تسرب السوائل أو الغازات، مما يحافظ على سلامة نظام الأنابيب وسلامته. -

تطبيقات متعددة الاستخدامات:

تجد الشفاه العمياء DIN2527 تطبيقًا في مختلف الصناعات، بما في ذلك النفط والغاز والمعالجة الكيميائية ومعالجة المياه وتوليد الطاقة وبناء السفن. يتم استخدامها في خطوط الأنابيب، وأوعية الضغط، وصهاريج التخزين لسد الفتحات غير المستخدمة أو المؤقتة، وعزل أجزاء من الأنابيب للصيانة أو الإصلاح، أو كوسيلة للفحص والاختبار. -

اختيار المواد:

تتوفر الشفاه العمياء في مواد مختلفة لتناسب ظروف التشغيل والوسائط المختلفة. تشمل المواد الشائعة الفولاذ الكربوني، والفولاذ المقاوم للصدأ، وسبائك الفولاذ، والسبائك غير الحديدية مثل النحاس أو البرونز. يعتمد اختيار المادة على عوامل مثل درجة الحرارة والضغط ومقاومة التآكل والتوافق مع السائل أو الغاز الذي يتم التعامل معه. -

تقييمات الضغط:

تم تصميم الشفاه العمياء DIN2527 لتحمل معدلات ضغط محددة، تتراوح من PN6 إلى PN100، وفقًا لمعايير DIN. يحدد تصنيف الضغط الحد الأقصى للضغط المسموح به الذي يمكن أن تتحمله الحافة بأمان دون المساس بسلامتها الهيكلية أو أداء الختم. من الضروري اختيار الشفاه العمياء بمعدل الضغط المناسب للتطبيق المقصود لضمان التشغيل الآمن والموثوق. -

خيارات التخصيص:

While DIN2527 blind flanges conform to standard dimensions and specifications, customization options are available to accommodate unique project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized blind flanges are often tailored to fit specific piping configurations and operating conditions.

What Is a Blind Flange?

A blind flange is a solid, circular plate used to seal off the ends of piping systems, valves, or pressure vessels. Unlike other different flange types, blind flanges lack a central bore, making them ideal for completely closing off a pipeline or opening. They are commonly utilized in various industrial applications, including oil and gas, chemical processing, water treatment, and power generation, where secure and leak-proof pipe closures are essential.

Blind flanges are available in a wide range of sizes and pressure ratings, conforming to industry standards such as ANSI, ASME, and DIN. Sizes range from small diameters, like a 2-inch blind flange, to larger options, such as 36 blind flanges, catering to diverse operational requirements. The design typically features bolt holes around the perimeter, allowing the flange to be securely fastened to a mating component, like a pipe flange or valve.

The primary purpose of a blind flange is to isolate sections of a pipeline for maintenance, testing, or system modifications without disrupting the entire operation. They also play a critical role in pressure testing, allowing operators to evaluate the system's capacity under specific conditions.

Materials for blind flanges include stainless steel, carbon steel, alloy steel, and other metals, ensuring compatibility with various operating environments, including high-temperature, high-pressure, or corrosive conditions. Some blind flanges also feature coatings or linings for additional durability.

Blind flanges are essential for ensuring safety, system integrity, and operational flexibility. Their robust design and adaptability make them indispensable in industrial piping systems, providing reliable sealing solutions and enhancing overall efficiency.

What Is a Blind Flange Used For

Pipeline Isolation

Blind flanges are commonly used to isolate sections of a pipeline for maintenance, repairs, or system upgrades. By sealing off the pipeline, operators can work on specific sections without interrupting the entire operation.

System Testing

In pressure testing scenarios, blind flanges enable operators to assess the strength and performance of the pipeline or vessel under controlled conditions. The flange helps maintain pressure within the system during testing, ensuring accurate results.

Future Expansion

Blind flanges can be installed at pipeline terminations where future expansions are anticipated. They temporarily seal the system, allowing additional components to be integrated later without significant modifications.

Safety in Shutdowns

During system shutdowns, blind flanges ensure that no residual fluids or gases escape, enhancing safety for maintenance crews and protecting the environment.

Preventing Contamination

In industries like food processing or pharmaceuticals, blind flanges are used to prevent contamination by securely sealing unused pipeline sections.

Blind Flange Types

Standard Blind Flanges

Standard blind flanges are flat, solid discs with no central bore. They are designed to fit a variety of piping systems and are often categorized by standards such as ANSI, ASME, and DIN. These flanges are versatile and used in applications with moderate pressure and temperature conditions.

Raised Face (RF) Blind Flanges

Raised face blind flanges feature a slightly elevated sealing surface. The raised face provides a better seal when paired with gaskets, making them suitable for higher-pressure applications in industries like oil and gas.

Flat Face (FF) Blind Flanges

Flat-face blind flanges have a uniform sealing surface that lies flush with the pipe flange. They are ideal for systems where flange surfaces must be evenly distributed to prevent damage, such as in low-pressure environments.

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges feature a grooved surface to accommodate metal gaskets. This design provides superior sealing, making them ideal for high-pressure and high-temperature systems, such as petrochemical plants.

Threaded Blind Flanges

Threaded blind flanges have threads on their inner surface, allowing them to be screwed directly onto a threaded pipe. They are commonly used in low-pressure systems and applications requiring quick assembly and disassembly.

DIN 2527 Blind Flange Advantages

The DIN 2527 blind flange is an essential component in piping systems, particularly in industrial applications where robust sealing is required. This type of flange offers several advantages, making it a preferred choice for many engineers and designers.

Firstly, one of the main benefits of the DIN 2527 blind flange is its ability to provide a secure and leak-proof seal. By covering the ends of pipes, it effectively blocks the flow, preventing any unwanted leaks or exposures. This is particularly critical in systems that transport hazardous materials, where safety and environmental protection are of utmost importance.

Secondly, the DIN 2527 blind flange is designed to withstand high pressure and temperature conditions, which ensures durability and long service life. Constructed from various materials, including stainless steel, carbon steel, and alloys, these flanges can be tailored to meet specific operational requirements, enhancing their reliability under extreme conditions.

Another advantage is the easy installation process. The blind flange can be easily bolted to the end of a pipe without requiring any special tools or complex techniques. This simplifies the assembly process and allows for quicker maintenance or modifications in the future.

Additionally, blind flanges are highly versatile and can be used in a range of applications, from oil and gas to water treatment and chemical processing. This versatility makes the DIN 2527 blind flange an excellent solution for diverse industries.

Moreover, using blind flanges can enhance the system's overall design by facilitating future expansions or modifications. Since they can be removed and replaced without extensive alterations to the piping layout, they provide flexibility in system management.

In summary, the DIN 2527 blind flange offers secure sealing, durability, ease of installation, versatility, and design flexibility, making it a vital component in many industrial piping systems. Its advantages contribute significantly to operational efficiency and safety, solidifying its status as a preferred choice in various applications.

تعتبر الفلنجات العمياء DIN2527 مكونات لا غنى عنها في أنظمة الأنابيب، مما يوفر إغلاقًا موثوقًا ومانعًا للتسرب لأطراف الأنابيب أو الفتحات. إن التزامها بمعايير DIN وتعدد الاستخدامات والخيارات القابلة للتخصيص يجعلها مناسبة لمجموعة واسعة من التطبيقات الصناعية حيث يعد الختم المحكم واحتواء الضغط أمرًا بالغ الأهمية. باستخدام الشفاه العمياء DIN2527، يمكن للمهندسين والمشغلين ضمان سلامة أنظمة الأنابيب الخاصة بهم وسلامتها وكفاءتها، مما يساهم في عمليات سلسة وخالية من المشاكل عبر الصناعات.